ASML has become Europe’s most valuable company by dominating one of the most critical technologies in modern chipmaking: extreme ultraviolet (EUV) lithography. These massive semiconductor lithography machines, often described as “chip printers,” cost up to $250 million each and are essential for producing the world’s most advanced chips used in artificial intelligence, high-performance computing, and data centers.

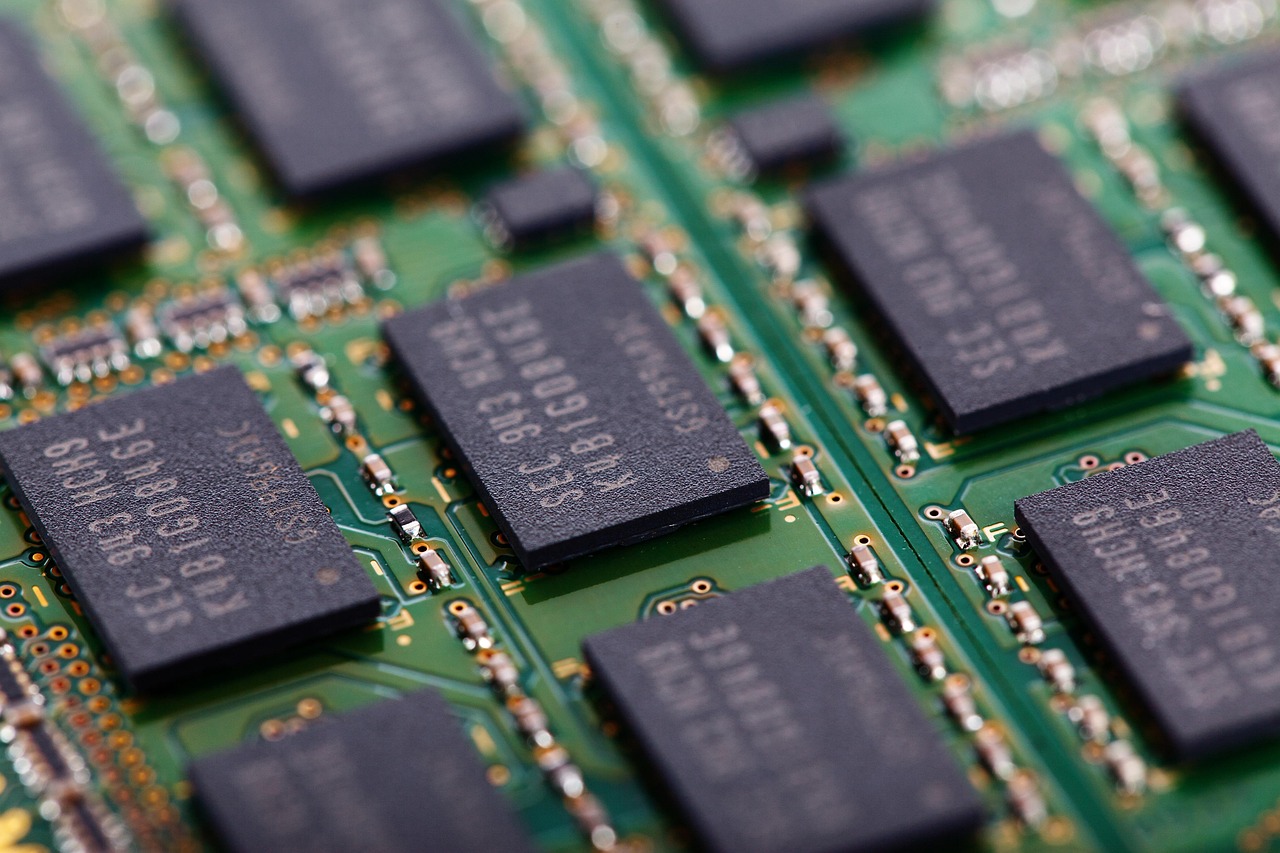

The surge in demand for ASML’s EUV systems is being driven by rapid advances in AI and the global expansion of data center infrastructure. Leading semiconductor manufacturers such as TSMC, Samsung, Intel, SK Hynix, Micron, and Rapidus rely on ASML’s technology to manufacture cutting-edge AI chips, including those designed for Nvidia. ASML currently holds a monopoly on EUV lithography machines, giving it a unique and powerful position in the global semiconductor supply chain, even as competitors in the U.S. and China attempt to develop alternatives.

ASML’s EUV machines are engineering marvels. Each system is roughly the size of a school bus and weighs around 150 tons, yet it operates at the nanometer scale. The machines project intricate circuit patterns onto silicon wafers using EUV light with a wavelength of just 13 nanometers. To put that into perspective, a single human hair is about 80,000 to 100,000 nanometers thick. This extreme precision enables higher chip performance, better energy efficiency, and greater scalability—key requirements for advanced AI processors.

Producing EUV light is one of the most complex processes in modern manufacturing. Tiny droplets of molten tin are fired 50,000 times per second and hit with some of the most powerful industrial lasers ever built, supplied by Germany’s Trumpf. The resulting light is directed by ultra-smooth mirrors from Zeiss, kept in a vacuum and polished to standards exceeding those of space telescopes. Meanwhile, the wafer stage levitates on magnetic fields and moves at speeds of up to 80 meters per second with astonishing accuracy.

Once assembled in the Netherlands, each EUV system is shipped in about 40 containers and flown by cargo aircraft to chipmaking facilities worldwide. In 2024 alone, ASML delivered 44 EUV machines, with analysts forecasting significantly higher shipments in 2026 and 2027 as global demand for AI chips continues to rise.

American Airlines CEO to Meet Pilots Union Amid Storm Response and Financial Concerns

American Airlines CEO to Meet Pilots Union Amid Storm Response and Financial Concerns  SpaceX Prioritizes Moon Mission Before Mars as Starship Development Accelerates

SpaceX Prioritizes Moon Mission Before Mars as Starship Development Accelerates  Nvidia CEO Jensen Huang Says AI Investment Boom Is Just Beginning as NVDA Shares Surge

Nvidia CEO Jensen Huang Says AI Investment Boom Is Just Beginning as NVDA Shares Surge  TSMC Eyes 3nm Chip Production in Japan with $17 Billion Kumamoto Investment

TSMC Eyes 3nm Chip Production in Japan with $17 Billion Kumamoto Investment  AMD Shares Slide Despite Earnings Beat as Cautious Revenue Outlook Weighs on Stock

AMD Shares Slide Despite Earnings Beat as Cautious Revenue Outlook Weighs on Stock  Jensen Huang Urges Taiwan Suppliers to Boost AI Chip Production Amid Surging Demand

Jensen Huang Urges Taiwan Suppliers to Boost AI Chip Production Amid Surging Demand  Instagram Outage Disrupts Thousands of U.S. Users

Instagram Outage Disrupts Thousands of U.S. Users  Nasdaq Proposes Fast-Track Rule to Accelerate Index Inclusion for Major New Listings

Nasdaq Proposes Fast-Track Rule to Accelerate Index Inclusion for Major New Listings  Washington Post Publisher Will Lewis Steps Down After Layoffs

Washington Post Publisher Will Lewis Steps Down After Layoffs  Prudential Financial Reports Higher Q4 Profit on Strong Underwriting and Investment Gains

Prudential Financial Reports Higher Q4 Profit on Strong Underwriting and Investment Gains  SoftBank Shares Slide After Arm Earnings Miss Fuels Tech Stock Sell-Off

SoftBank Shares Slide After Arm Earnings Miss Fuels Tech Stock Sell-Off  SpaceX Pushes for Early Stock Index Inclusion Ahead of Potential Record-Breaking IPO

SpaceX Pushes for Early Stock Index Inclusion Ahead of Potential Record-Breaking IPO  OpenAI Expands Enterprise AI Strategy With Major Hiring Push Ahead of New Business Offering

OpenAI Expands Enterprise AI Strategy With Major Hiring Push Ahead of New Business Offering  Global PC Makers Eye Chinese Memory Chip Suppliers Amid Ongoing Supply Crunch

Global PC Makers Eye Chinese Memory Chip Suppliers Amid Ongoing Supply Crunch  Nintendo Shares Slide After Earnings Miss Raises Switch 2 Margin Concerns

Nintendo Shares Slide After Earnings Miss Raises Switch 2 Margin Concerns  Hims & Hers Halts Compounded Semaglutide Pill After FDA Warning

Hims & Hers Halts Compounded Semaglutide Pill After FDA Warning  Sony Q3 Profit Jumps on Gaming and Image Sensors, Full-Year Outlook Raised

Sony Q3 Profit Jumps on Gaming and Image Sensors, Full-Year Outlook Raised